ShieldAg Machine Shop

For over 15 years, ShieldAg Equipment has operated as a job shop machine shop, serving a variety of industries:

Agricultural equipment and parts manufacturers, both for our own equipment line and as a certified supplier to the largest Ag OEM companies

Automotive in-plant equipment companies

Aerospace parts supply manufacturers

Wind Energy nacelle manufacturing

Turf and ATV control cabling manufacturers

Hardware suppliers

Steel building components suppliers

In-plant maintenance companies

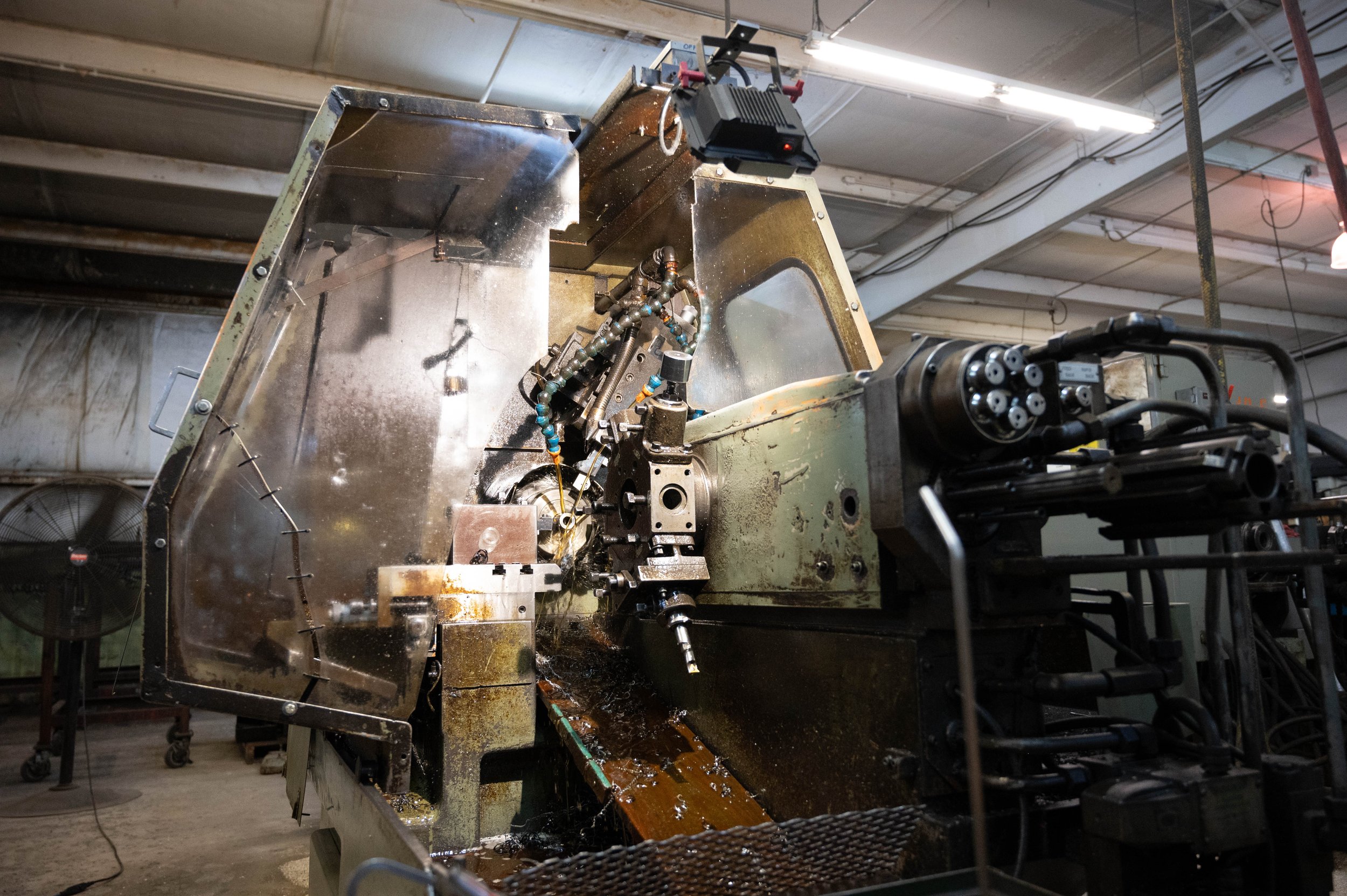

With six CNC machining centers and a CNC lathe, along with automatic screw machines, a full complement of manual machines, tool grinding & inspection equipment, and a complete set of fabricating, stamping, and welding equipment, ShieldAg provides turnkey solutions for your farm-out job requirements.

“I would recommend ShieldAg for any machine work needs. We have used them for a number of years with excellent results.”

-

ShieldAg is certified to ISO-equivalent quality standards required by two major OEMs. We maintain fully certified inspection equipment, ensuring precision and adherence to the strictest quality requirements across every project.

-

At ShieldAg, we use SolidWorks, an industry-leading design software that allows for seamless integration of your CAD files directly into our production process. With SolidWorks, we can:

Efficient Prototyping & Manufacturing: Transfer your designs into production quickly, reducing lead times and ensuring precision.

Simulation & Optimization: Test and refine designs virtually to guarantee performance and quality before manufacturing begins.

Collaborative Development: Work closely with our engineers to fine-tune components and meet your exact specifications.

SolidWorks helps us deliver reliable, high-quality parts. It’s the perfect tool for custom parts, one-off prototypes, or full-scale production runs.

-

Mazak Ultra AJV 25 /405N Vertical Machining Center M-32

Mazak Ultra 650 Horizontal Machining Center Mazatrol Plus (2 units)

Mazak Ultra 550 Horizontal Machining Center Mazatrol Plus

Mazak V7.5 vertical CNC Mill 6M

Okuma LB25 CNC Lathe

-

40” X 20” X 18” With Pallet Changer

40” X 31.5” X 29.5” Dual Pallet (2 units)

28” X 35” X 25” Dual Pallet

30” X 16” X 20”

24” Diameter X 30” Between Centers

-

Myanomatic 3” Automatic screw machine

Myanomatic 2” Automatic screw machine

-

Bridgeport with DRO

Harrison M350 Engine Lathe

Grizzly Mill Drills G 3358 (3 units)

Cincinnati Tool Grinder

Warner Swasey Turret Lathe

-

Lincoln Power Mig 256 Model 11780

Lincoln Power Mig 450

Piranha RP50 with Full Set of All Tooling

Various Metal Stamping Presses & Spot Welders